Polydicyclopentadiene (PDCPD) is a new type of material in the field of polymer materials, known as "incredible" in Europe and the United States belongs to the high-end molding manufacturing new materials, which has the advantages of lightweight, high strength, physical balance, green environmental protection, industrial closure, is an ideal material to replace fiberglass reinforced plastic, traditional sheet metal parts, part of the plastic parts and so on. PDCPD material has both high impact strength and high bending modulus, belongs to elastic deformation-based ductile material, its products are lightweight, high strength, balanced physical properties, lightweight (specific gravity close to water), free modeling design, not only has a high modulus of elasticity, but also has a very high impact resistance, high creep resistance, thermal stability, and outstanding resistance to corrosion, insulation, weathering, and wave transmittance, and at the same time, has the following characteristics PDCPD-RIM formulations using tungsten-molybdenum catalyst system, the use of C9 fraction of DCPD, the production of PDCPD new material products with unique performance, comprehensive performance is better than Japan and the United States, focusing on the low price, good process performance, small deformation of the parts, environmental protection, raw material sources are not restricted, the current annual output of 100,000 tons of PDCPD-RIM combination of formula materials production base, the production of PDCPD-RIM combination of formula materials, the annual output of 100,000 tons. At present, the annual output of 100,000 tons of PDCPD-RIM combination formula material production base has been put into production, and realize the export to Europe, domestic and foreign customers reflect good.

Green Advantage:

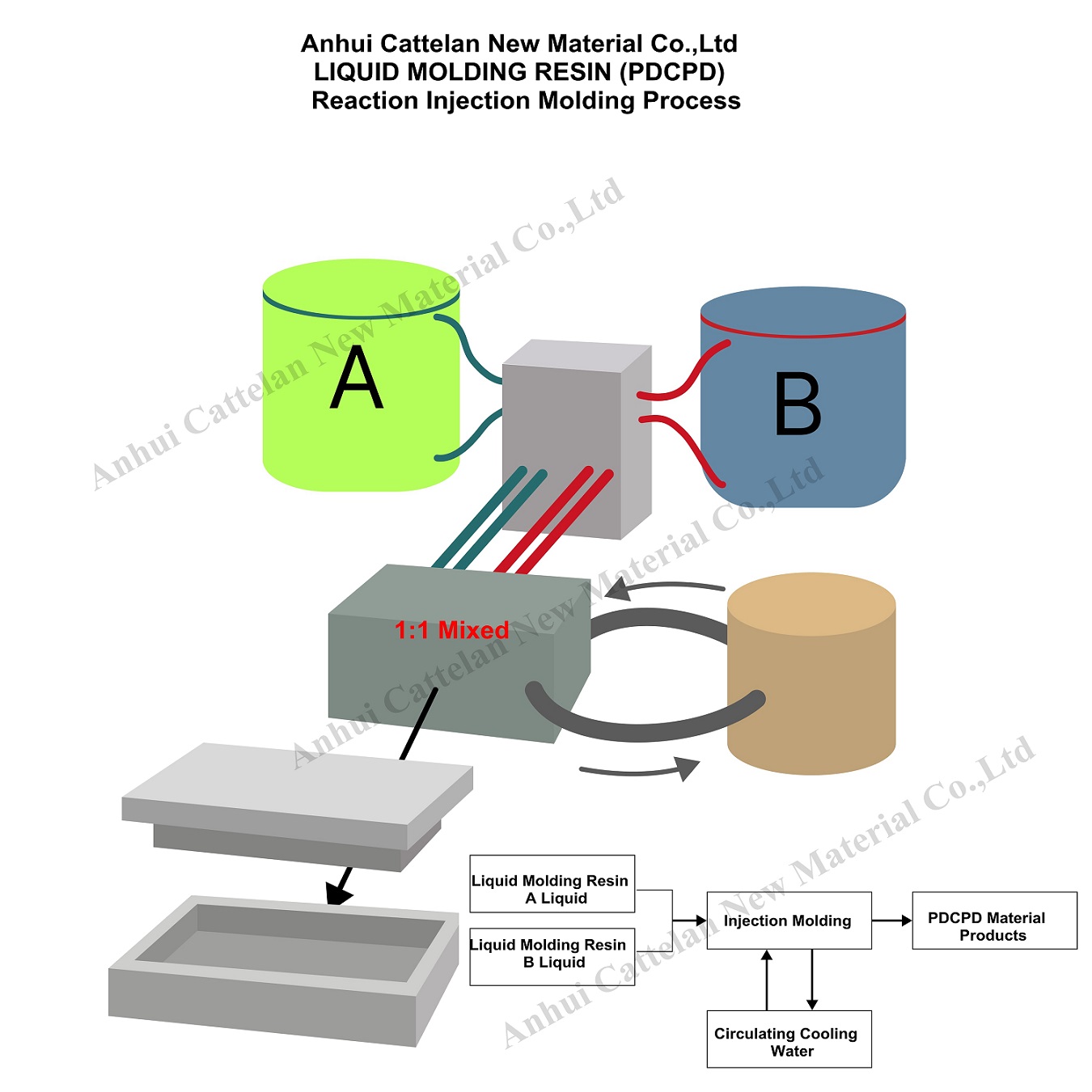

Dicyclopentadiene Injection Resin (DCPD-RIM) Production: It is a paste resin composed of cyclopentadiene olefin (DCPD) as the main raw material, assisted by polymer rubber, antioxidant, main and auxiliary catalysts, time regulator, etc. It consists of A and B two-component components, and all the added substances are in line with the international ROSH norms, and it does not contain any substances in the REACH SVHC list, and it complies with the national Occupational health requirements.

PDCPD product production: DCPD-RIM is the raw material, without adding any other auxiliary materials, the molding process is reaction injection molding, the whole process is an exothermic reaction, and energy consumption is very small (only 1/4 to 1/2 of the energy consumption of plastic production). No water is involved in the production of the products, no waste residue is produced, and only trimmings and wastes are produced, so the emission is almost zero. The material is highly flame retardant (up to UL94-HB grade) and does not produce toxic or hazardous substances when burned, which is in line with the international "Banned Substances Program" specification. Edge waste can be harmlessly recycled, realizing the complete closure of the whole industrial chain, which is a model of "green chemistry", with the industrialized manufacturing embodiment of "fast, good and economical", and very much in line with the requirements of China's Carbon Dafeng Carbon Neutral Strategy and the new concept of sustainable development.

Advantage of energy saving: DCPD polymerization reaction is exothermic reaction, molding does not require high mold temperature; therefore, the processing of PDCPD products has very low energy consumption, and the energy required in the process of raw material preparation and molding is much lower than that of traditional plastics such as PC, PA, etc. According to statistics, the energy required for every 1 kg of PDCPD products is only 1/4 of that required for PP products of the same quality, and 1/10 of that for PC products.

According to statistics, the energy required for producing 1 kg of PDCPD products is only 1/4 of that required for producing PP products of the same quality and 1/10 of that required for PC products; in terms of greenhouse gas emissions, according to the data of the relevant departments, the CO2 emission for every 1 kg of PDCPD products produced in 2008 was about 2.4 kg; it is expected that the CO2 emission for every 1 kg of PDCPD products produced in 2015 will only be about 1 kg. It is expected that in 2015, the CO2 emission per 1 kg of PDCPD products will only be about 1 kg. Using injection molding, CO2 emissions were as high as 7.2 kg per kg of ABS or PC produced in 2008, and although this is expected to decrease to about 4.1 kg in 2015, the total CO2 emissions are still four times higher than those of PDCPD products.

The entire production process of PDCPD formulations and PDCPD products does not involve water, no waste residue is produced, and the emissions are almost zero, which greatly saves and water resources.

In terms of recycling: PDCPD's environmental friendliness is also reflected, PDCPD products can still be processed and crushed to granulate the waste, as thermoplastics such as PP, PE filler recycling, more effective recycling can be generated through anaerobic cracking of activated charcoal and fuel oil, to achieve 100% harmless recycling. In addition, when PDCPD products are used in transportation and other fields, they can reduce the weight of the body, thus greatly improving fuel economy, saving fuel and reducing emissions.