-

Make a Call : +86 13339003661

-

Get A Estimate : sales@cattelanpdcpd.com

Make a Call : +86 13339003661

Get A Estimate : sales@cattelanpdcpd.com

PDCPD new material is a green new material, the features of lightweight, high strength, rigid and flexible, impact resistance, corrosion resistance, weather resistance and insulation are very outstanding.

Item Name: :

PDCPD-RIM resin B LiquidOrder(MOQ): :

4 drums A and 4 drums BPayment : :

50% deposit with the balance before shippingProduct Origin : :

Bengbu, Anhui, ChinaColor: :

transparent and light yellowShipping Port : :

ShanghaiLead Time : :

20-35daysNet Weight : :

195kgs/barrelProduct Description

Polydicyclopentadiene(PDCPD) is a crosslinked three-dimensional mesh structure engineering plastics made of dicyclopentadiene (DCPD) as the raw material and polymerized under the action of catalyst. The appearance of polydicyclopentadiene is transparent liquid, resistant to general acids and alkalis and organic solvents, with high strength, high toughness, impact resistance, water resistance, low temperature resistance, electrical insulation, environmentally friendly, easy to mold and other excellent characteristics, downstream can be applied to a wide range.

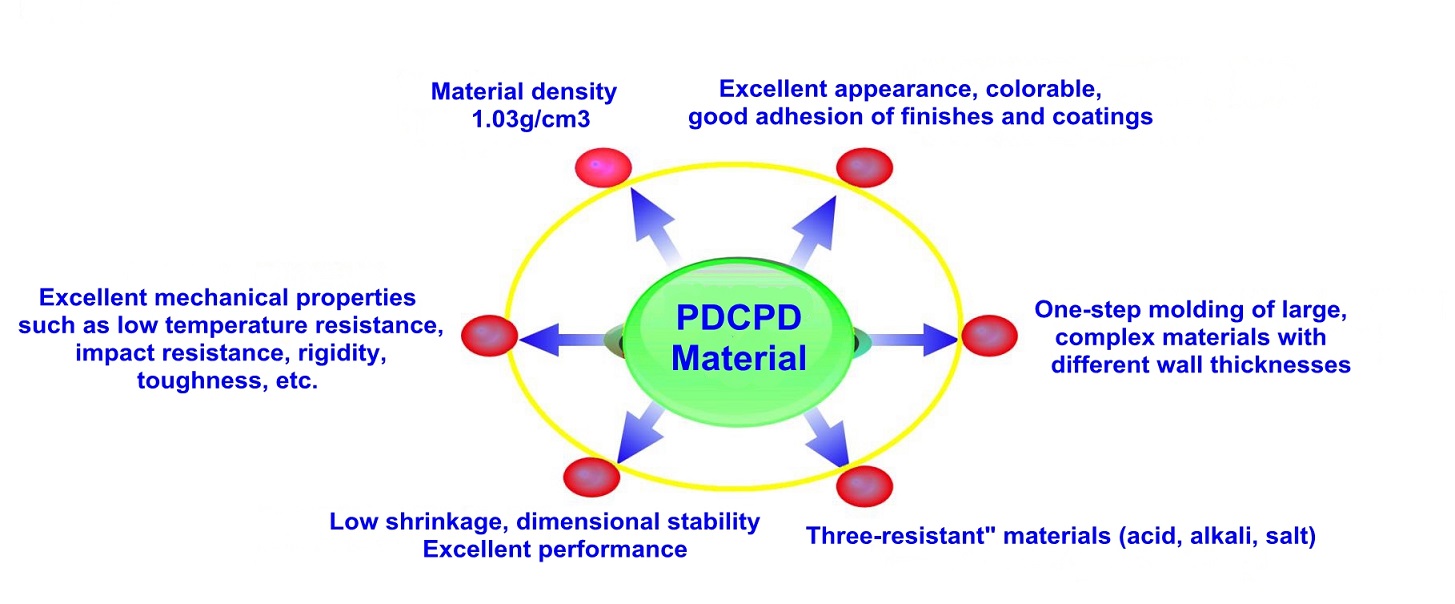

Outstanding Feathers of PDCPD Material

Wide Usages of PDCPD Products

PDCPD (Polydicyclopentadiene ) does not contain any fiber-reinforced composite material, and the production process is gas-protected injection molding. It has been used in automotive parts, such as bumpers, spoilers, instrument panels, fenders, etc. It can also be used in shells with high strength requirements, such as battery pack shells.

|

|

|

The Properties References of PDCPD vs Fiberglass, Carbon Fiber Composite,Mild Steel and Aluminum Alloy

| Property | PDCPD | Fiberglass, Carbon Fiber Composite | Mild steel, Aluminum Alloy |

| Elongation at break |

>5%

|

<2%

|

>10%

|

| Material Properties | Ductile materials | Brittle material | Ductile materials |

| Deformation of a stressed principal | Elastic deformation | Microcrack → fracture | Plastic Deformation |

| Homogeneity | Isotropic | Anisotropic | Isotropic |

| Physical Stability | Low performance dispersion | Large performance dispersion | Low performance dispersion |

| Stress analysis | Easy | Difficult | Easy |

| Temperature-dependent stress | Good | Poor | Good |

| Static load condition | Suitable | Suitable | Suitable |

| Dynamic load condition | Suitable | Not suitable | Suitable |

| Shock load | Suitable | Not suitable | Suitable |

Conclusion:

PDCPD materials and metal materials are isotropic ductile materials, which can be used for equal strength, equal stiffness structure design and strength conversion.

PDCPD materials have a high degree of freedom in design, and the overall stiffness of components can be further improved through shape design, and the use of PDCPD materials instead of mild steel can reduce weight by about 40%;

By optimizing the structural design, PDCPD material can be replaced with aluminum alloy material to achieve equal weight, with higher impact deformation resistance than aluminum alloy, and better structural and process implementation characteristics.

Hot Tags :